:330 8F., No. 69, Jingguo 1st Road, Taoyuan District, Taoyuan City, Taiwan

:03-325-0690

:sales@liwattx.com

- Total:{{ cartCount }}

-

-

Service

ODM Service

We offer ODM (Original Design Manufacturing) services that go beyond traditional OEM (Original Equipment Manufacturing), encompassing product research, design, and optimization. For lithium batteries, we provides a comprehensive end-to-end solution—from concept development to mass production—ensuring products meet market demands and maintain a competitive edge.

1. Product Research and Design

-

◆ Market Research and Demand Analysis:

■ Study battery requirements across various industries.

■ Analyze market trends and provide forward-thinking product solutions tailored to specific markets.

-

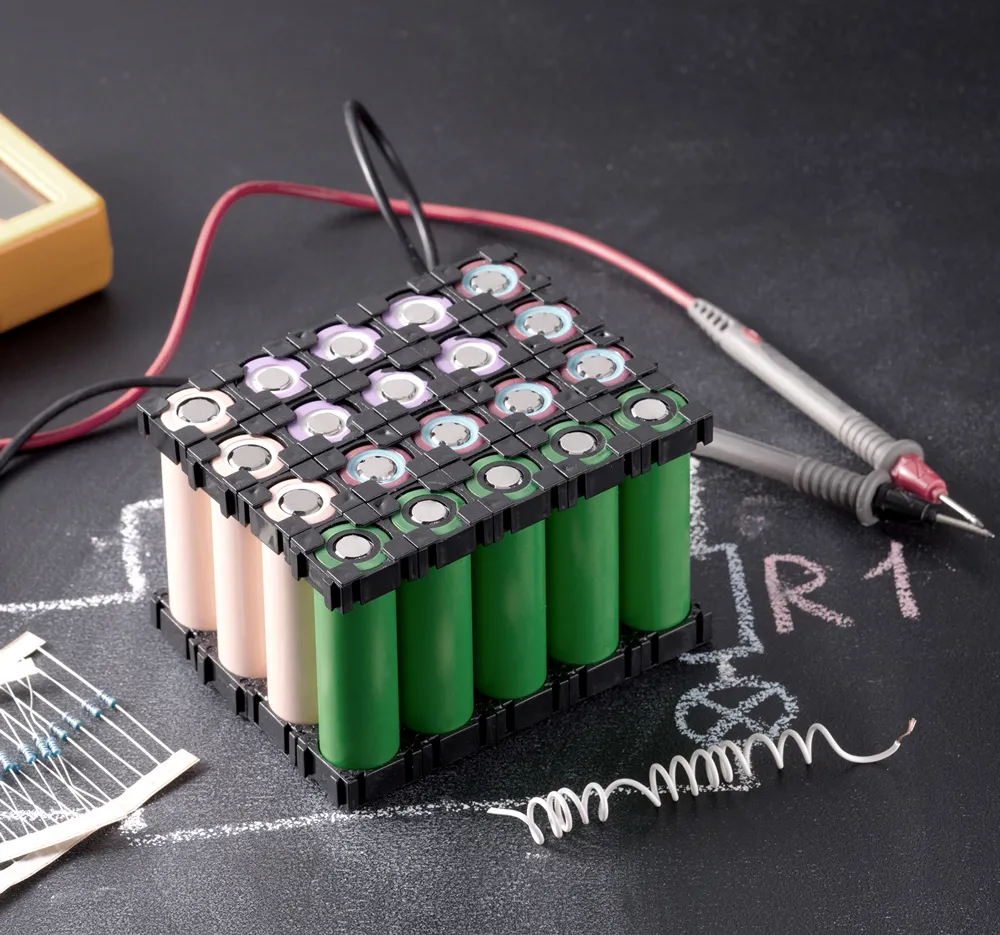

◆ Battery Solution Design:

■ Select appropriate battery types (Li-ion, LiPo, LiFePO4, solid-state, etc.).

■ Customize battery voltage, capacity, size, and shape to optimize durability and load performance.

■ Develop solutions for high discharge rate, high energy density, or lightweight battery packs.

-

◆ Smart BMS Development:

■ Design high-safety Battery Management Systems (BMS) with overcharge, over-discharge, and short-circuit protection.

■ Support smart communication protocols (CAN, UART, RS485) for remote monitoring and data analysis.

■ Customize Bluetooth/WiFi features for real-time battery status monitoring via mobile apps.

-

◆ Thermal Management Solutions for Enhanced Lithium Battery Safety :

■ LiWattX is committed to addressing thermal issues caused by lithium battery modules or ICs on PCBs, enhancing application safety.

-

◆ Appearance and Structural Design:

■ Custom battery enclosure options (pouch, plastic casing, aluminum alloy, carbon fiber, etc.).

■ Waterproof, shockproof, and temperature-resistant designs for harsh environments.

2. Manufacturing and Process Optimization

-

◆ Supply Chain Management and Material Selection:

■ Source high-quality battery cells from China, Taiwan, Japan, and South Korea.

■ Ensure the reliability of key components such as BMS chips, connectors, and wiring.

-

◆ Efficient Production Processes:

■ Utilize automated production equipment to enhance consistency and efficiency.

■ Apply advanced welding and sealing technologies to improve battery stability and durability.

-

◆ Prototyping and Mass Production:

■ Conduct small-scale trial production to refine processes before full-scale manufacturing.

3. Quality Testing and Certification Support

-

◆ Battery Safety Testing:

■ Perform charge/discharge cycles, overcharge, over-discharge, and short-circuit protection tests.

■ Conduct high/low temperature, vibration, and drop tests to ensure reliability under extreme conditions.

-

◆ International Certification Support:

■ Obtain necessary certifications for target markets (USA, Europe, Southeast Asia, Middle East, etc.), including UN38.3, CE, FCC, UL, IEC62133, etc.

■ Provide MSDS and Dangerous Goods Transportation Reports, ensuring compliance with global transport regulations.

4. Brand Customization and Software Development

-

◆ Custom Branding and Appearance:

■ Print custom logos and labels on battery housings.

■ Design personalized packaging, user manuals, and product documentation.

-

◆ Software and App Development:

■ Develop proprietary battery management software for PC and mobile monitoring.

■ Integrate intelligent scheduling and remote diagnostics to enhance battery operation and maintenance.

5. Logistics

-

◆ Global Logistics Services:

■ Handle the transportation of hazardous batteries in compliance with international regulations.

■ Offer multiple shipping options (air and sea freight) to optimize delivery efficiency.

■ If you require ODM services for lithium batteries, please share your specific product requirements. We will provide customized R&D and manufacturing solutions to help you gain a competitive edge in the market!